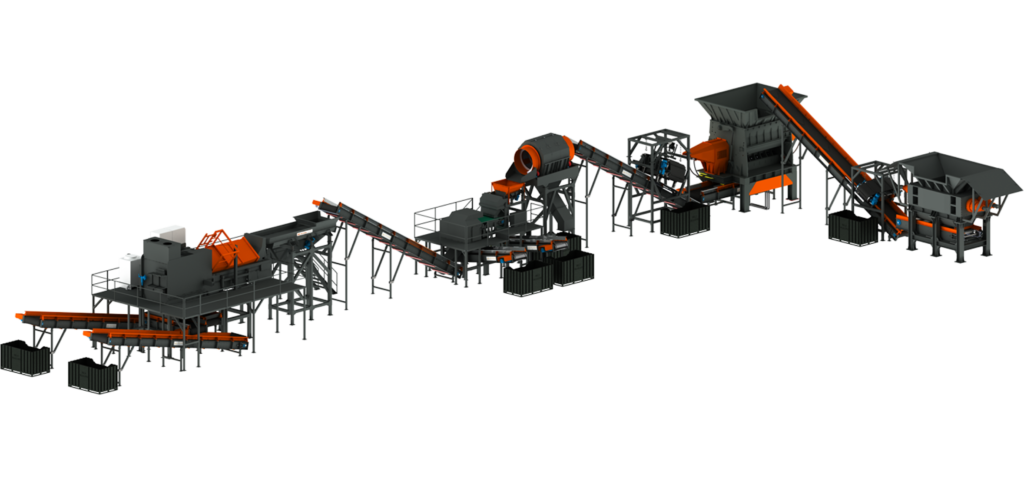

Aluminum recycling system

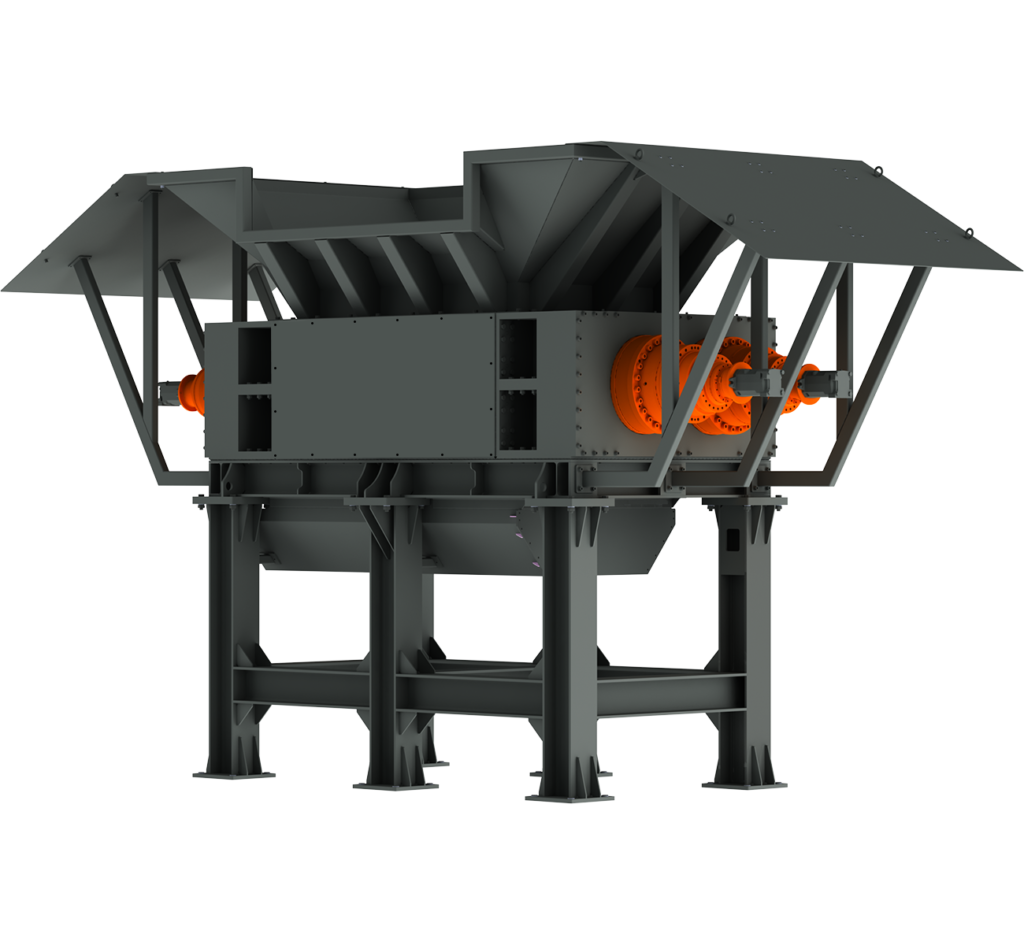

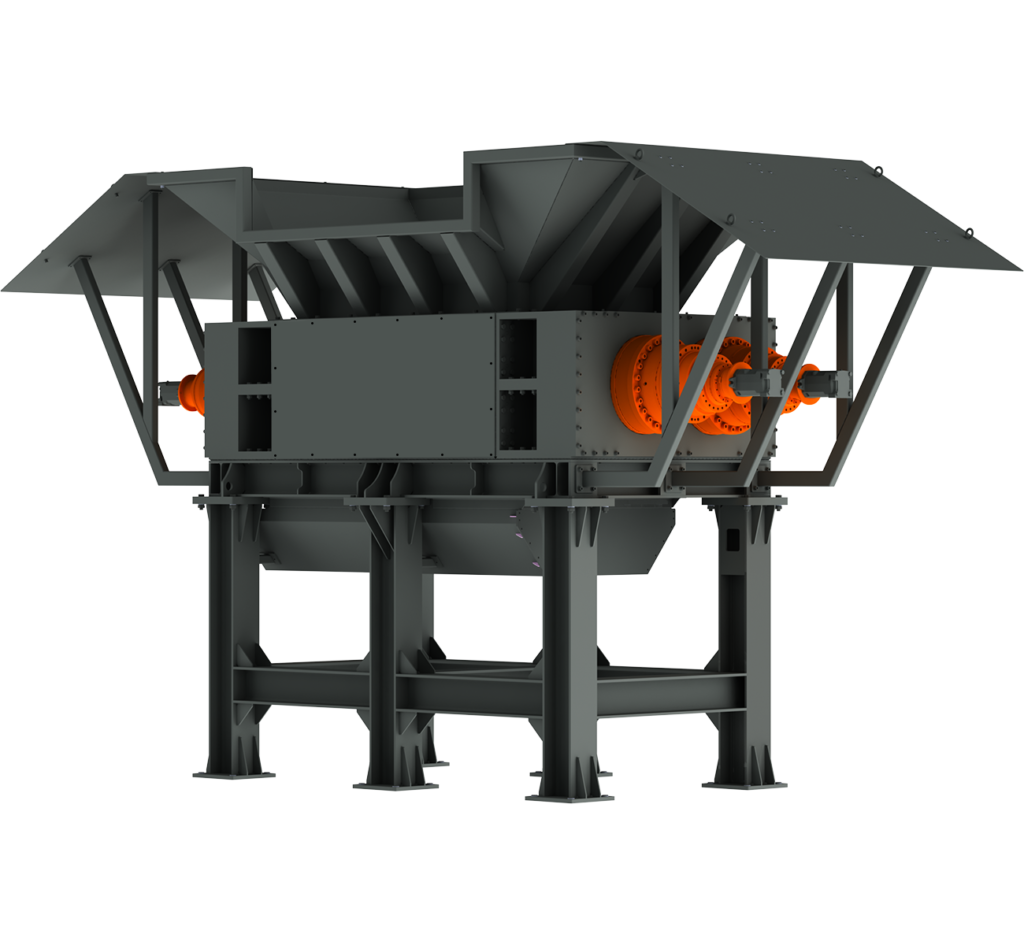

Double Shaft Shredder

The high-capacity crushing machine offered by GMS Machine is a specially designed solution for the future of recycling. This unique machine can effectively separate materials other than aluminum in scrap materials. The moving blades, operated with two separate rotors, efficiently break down materials into small pieces, optimizing your recycling processes. Additionally, the blades on the rotor are easily replaceable, making maintenance and operation processes smoother. This machine represents a significant step in improving your waste management and recycling processes. As part of our mission to contribute to a sustainable future, GMS Machine takes pride in introducing this important device to the industry. We are happy to emphasize our role in recycling and take a step towards a cleaner tomorrow

Double Shaft Shredder

The high-capacity crushing machine offered by GMS Machine is a specially designed solution for the future of recycling. This unique machine can effectively separate materials other than aluminum in scrap materials. The moving blades, operated with two separate rotors, efficiently break down materials into small pieces, optimizing your recycling processes. Additionally, the blades on the rotor are easily replaceable, making maintenance and operation processes smoother. This machine represents a significant step in improving your waste management and recycling processes. As part of our mission to contribute to a sustainable future, GMS Machine takes pride in introducing this important device to the industry. We are happy to emphasize our role in recycling and take a step towards a cleaner tomorrow

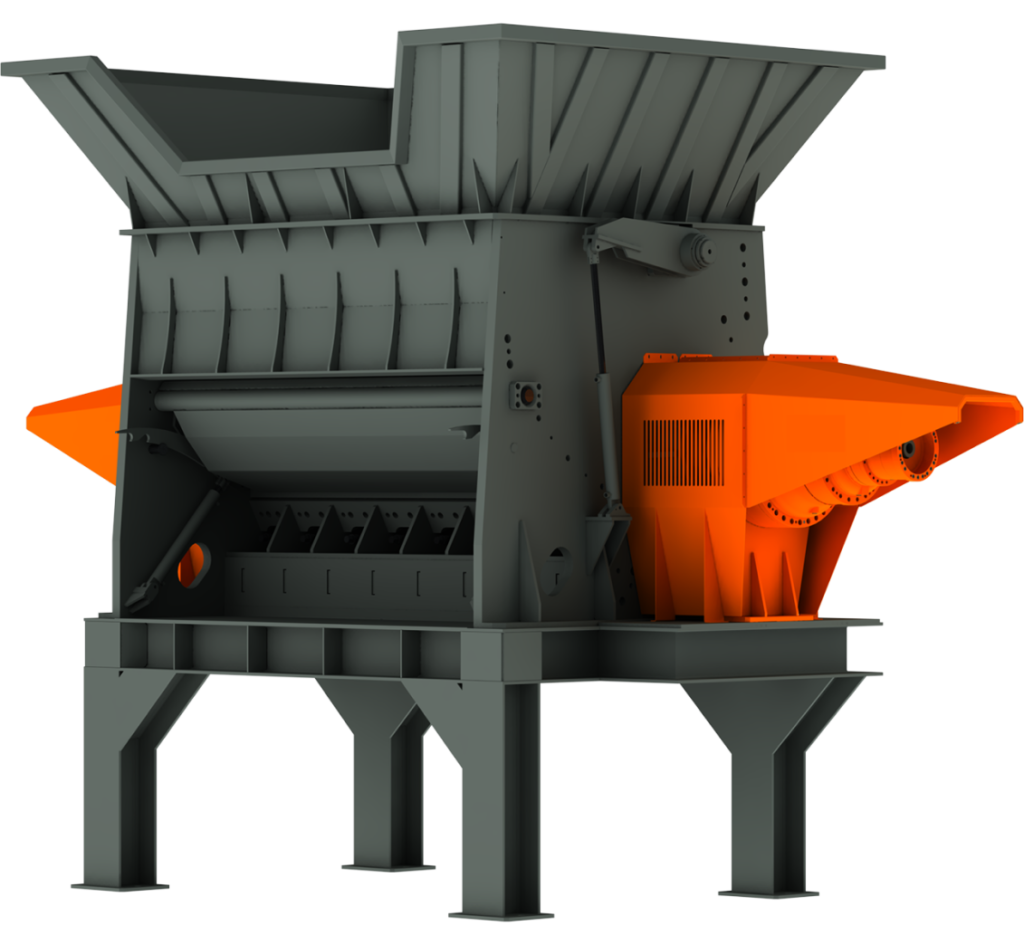

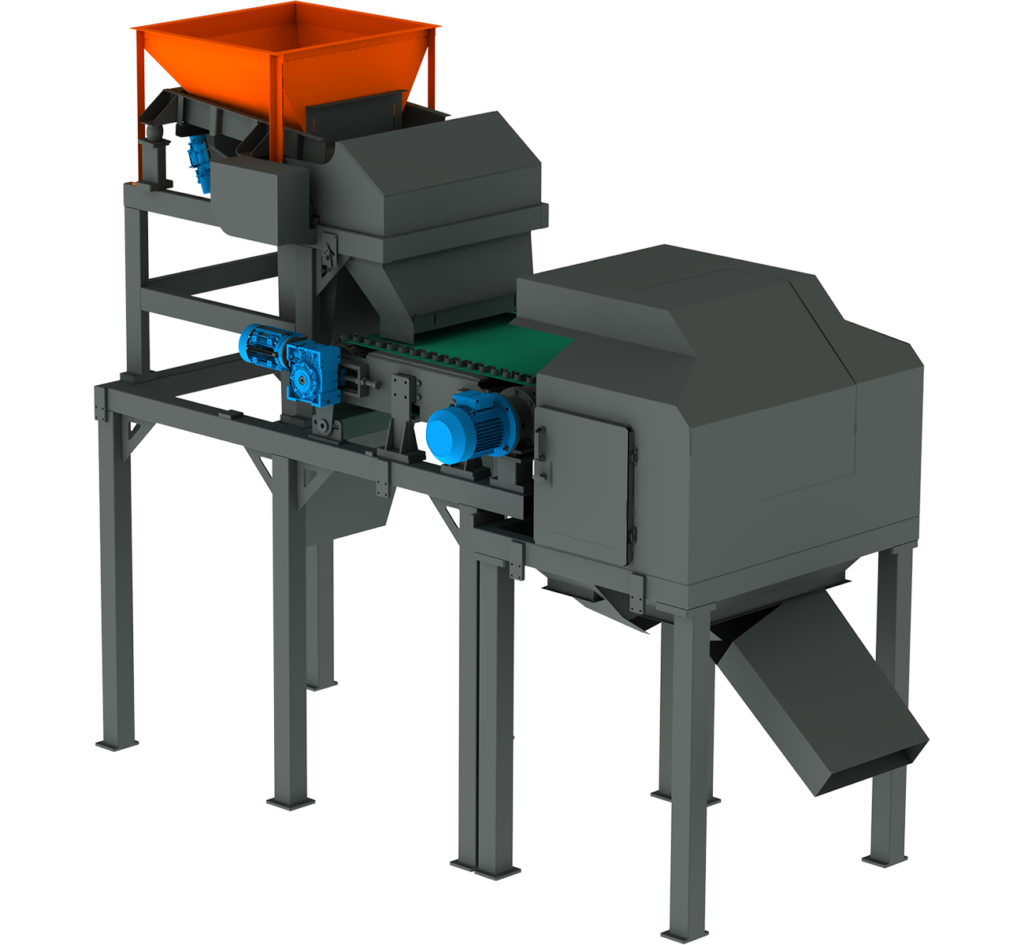

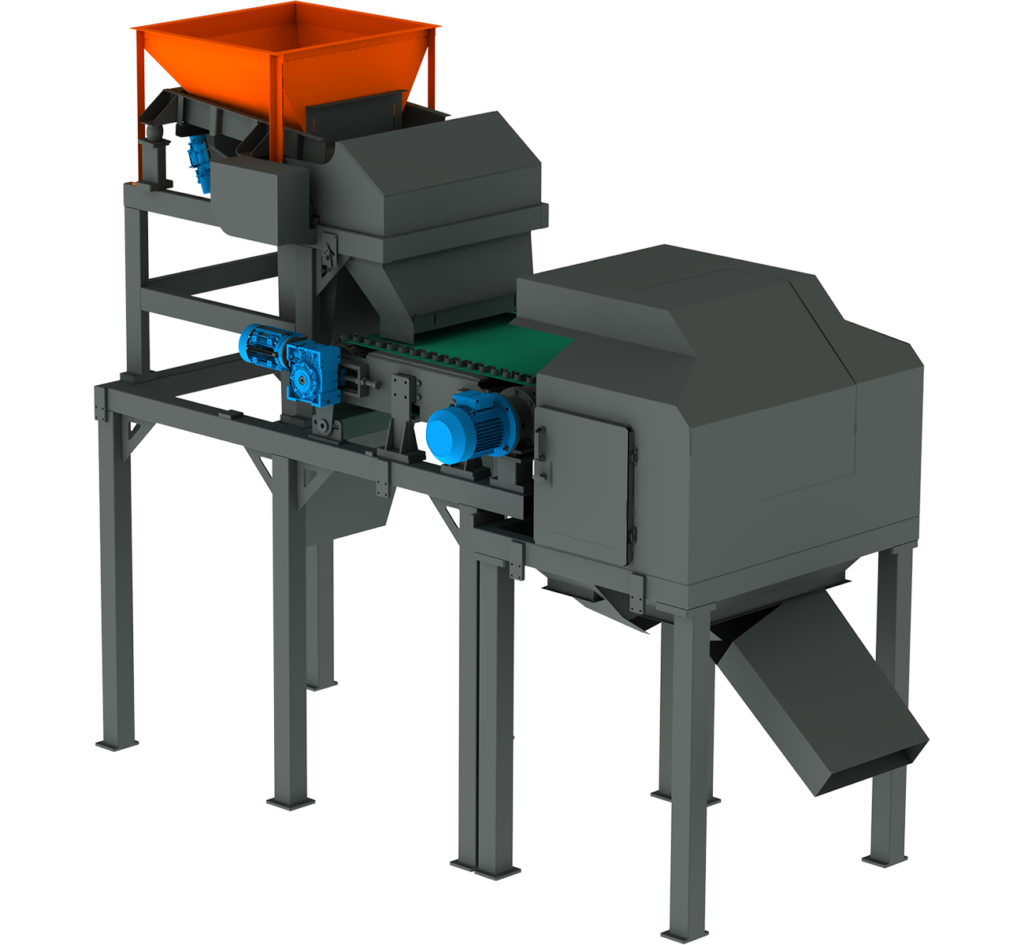

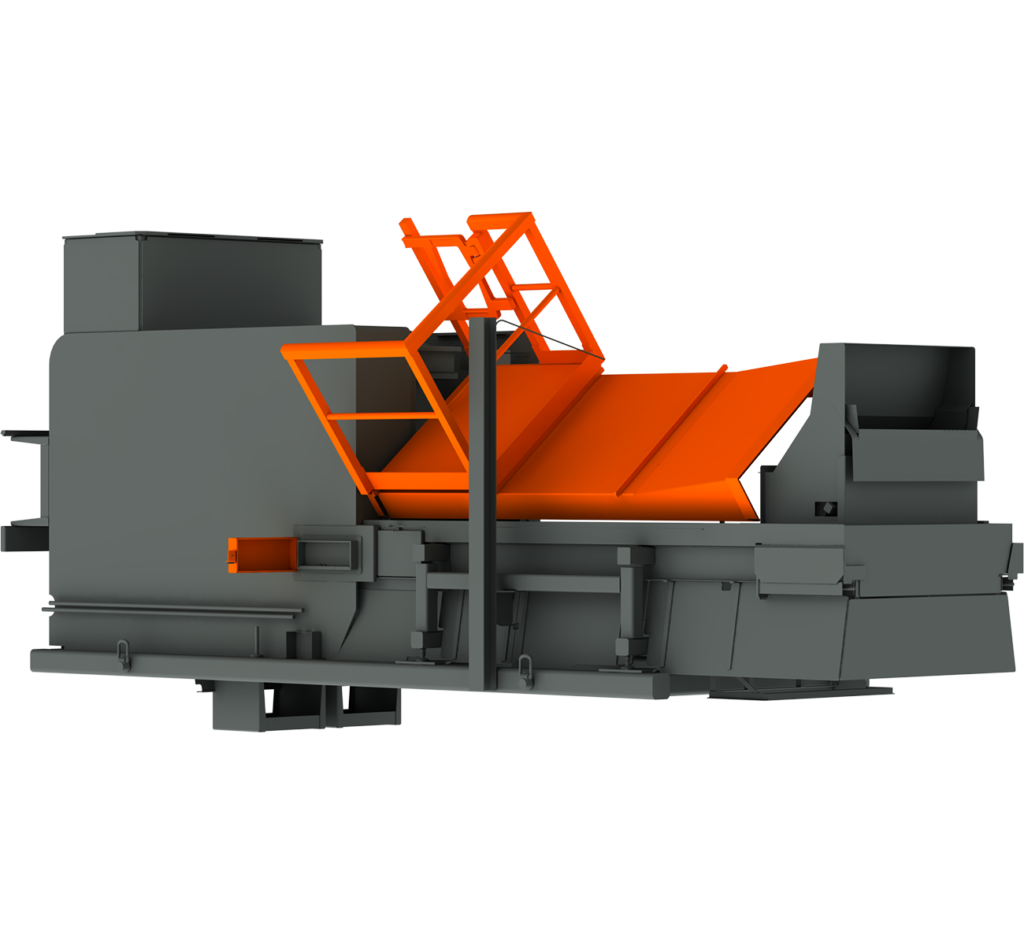

Single Shaft Shredder

The high-capacity crushing machine we offer at GMS Machine is a specially designed solution for the future of recycling. This unique machine, with its fixed and movable blades, is developed to effectively separate materials other than aluminum in scrap, enabling the most efficient aluminum recycling. With features such as the feeding arm and special rotor, along with the easy replaceability of blades, processes occur more quickly and efficiently. This machine not only improves waste management and recycling processes but also serves as an indication of our commitment to preserving our natural resources. At GMS Machine, we take pride in introducing this significant device to the industry as part of our mission to contribute to a sustainable future. We are happy to emphasize our role in recycling and take a step towards a cleaner tomorrow.

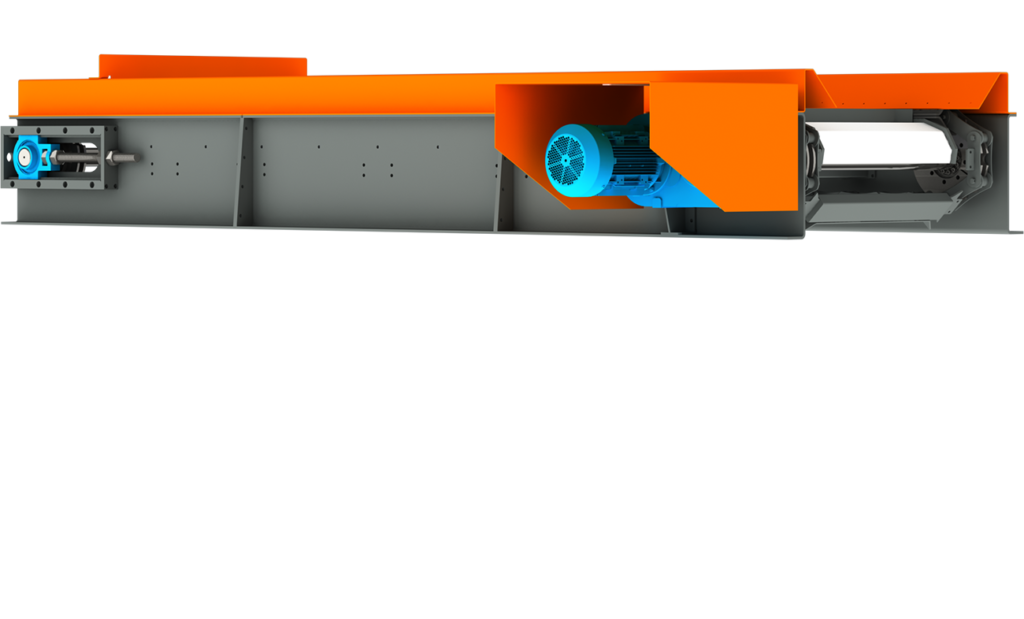

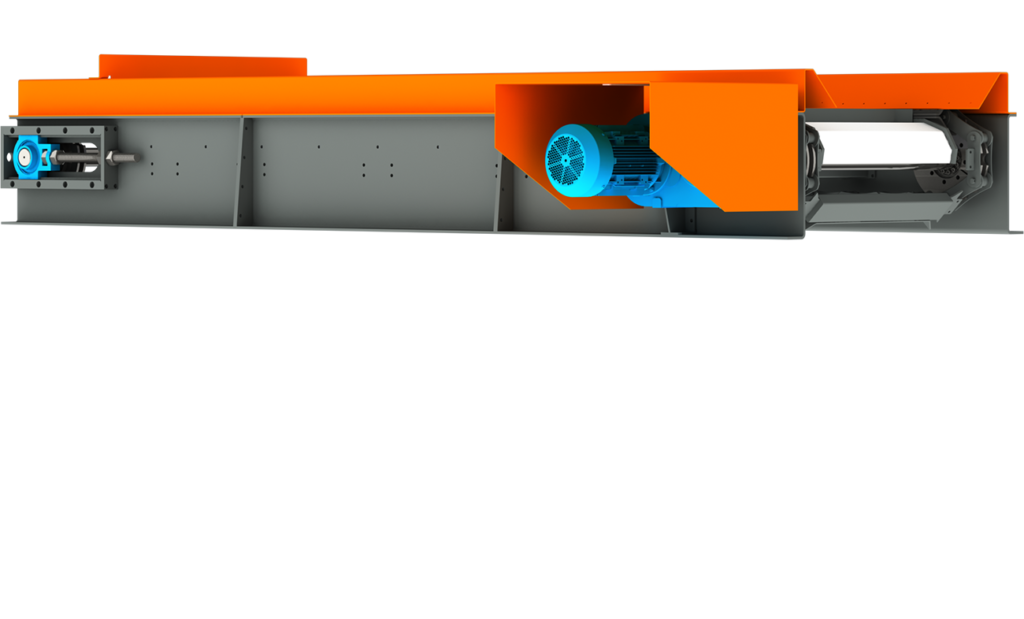

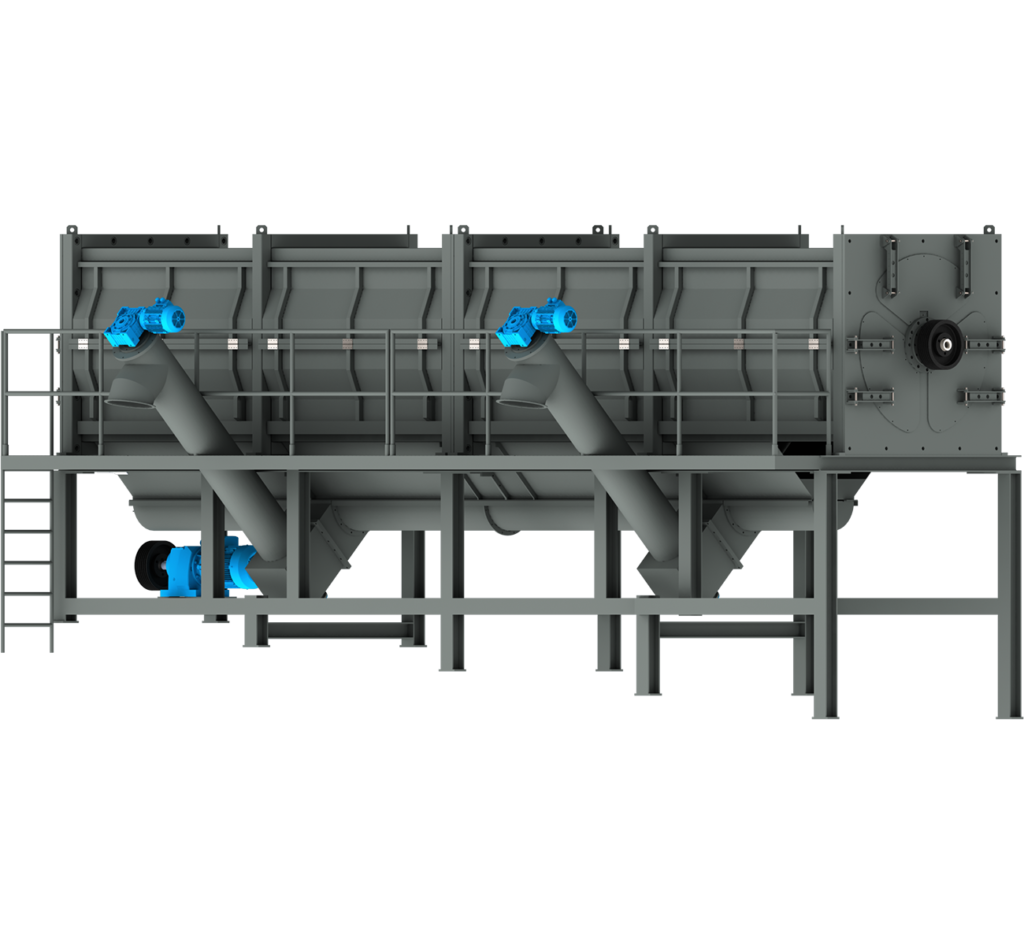

Scraper Conveyor

You won’t encounter situations like belt cleaning or tearing. Additionally, there is no need for roller and drum replacements. The use of a scraper conveyor results in time and cost savings.

Scraper Conveyor

You won’t encounter situations like belt cleaning or tearing. Additionally, there is no need for roller and drum replacements. The use of a scraper conveyor results in time and cost savings.

Magnetic Separator

A Magnetic Separator is an equipment used in aluminum recycling lines. Magnet systems are used to separate magnetic metals (ferromagnetic metals) from metal mixtures. This increases the efficiency of the recycling process and allows for the obtainment of pure aluminum.

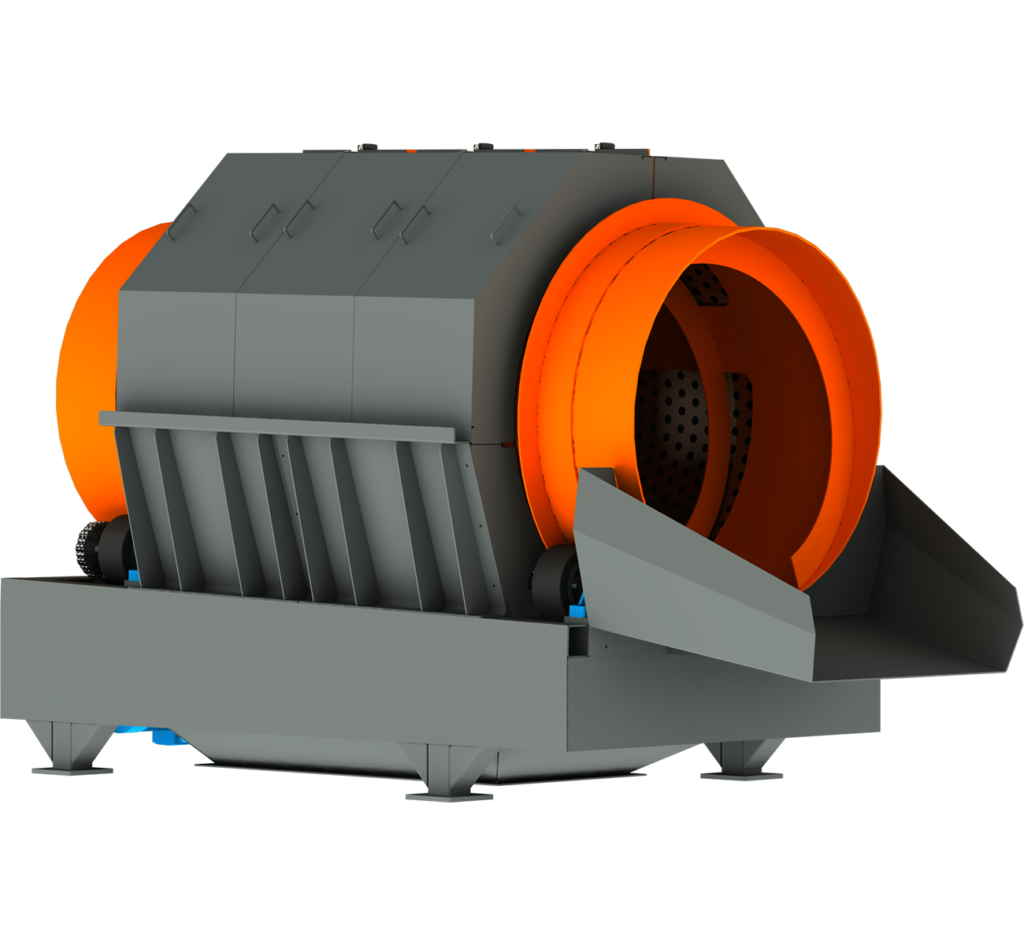

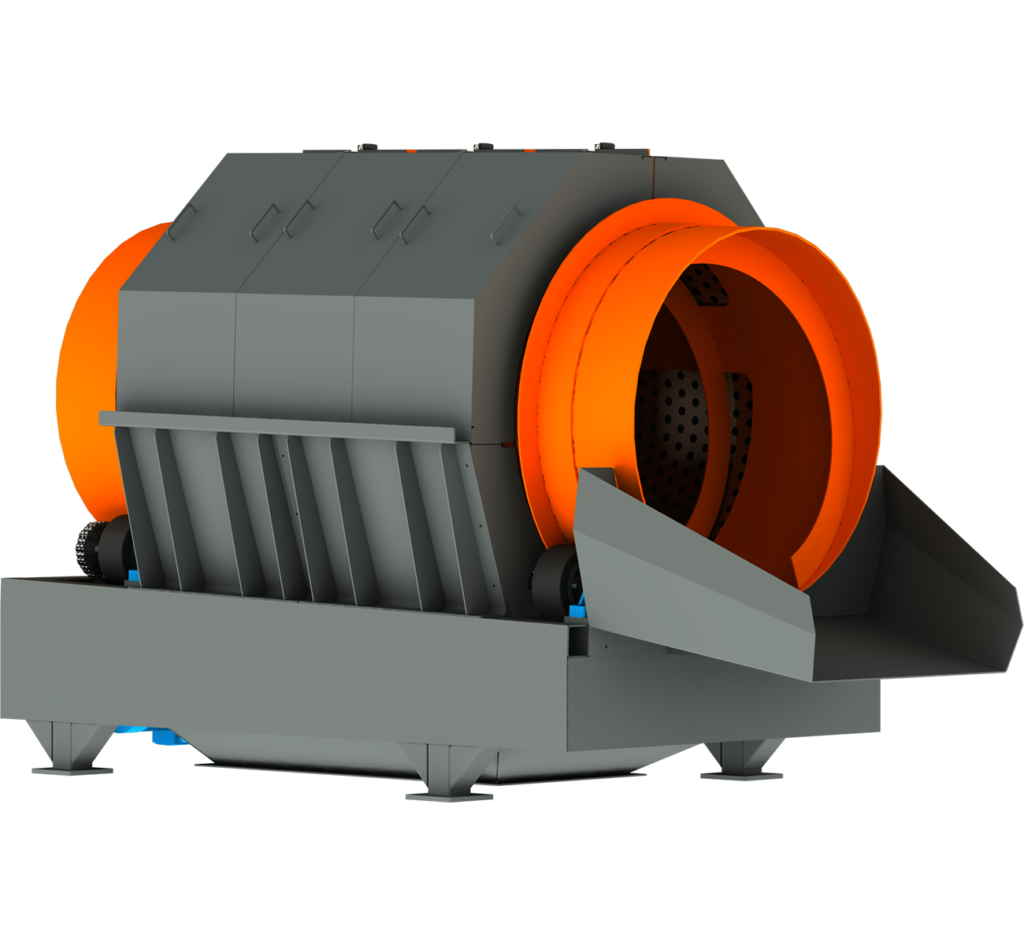

Rotary Screen

Rotary screens play a critical role in material conveying processes and are utilized in various industries.

Screws are generally produced in various standards, including pipe type, U type, and vertical type. The Rotary Screen produced by GMS Machine is a fundamental component in recycling processes, specifically designed as a durable and high-capacity equipment to clean and separate your materials. This equipment helps isolate valuable materials in a pure form by separating unwanted small particles and dust. As a result, your recycling processes become more effective and efficient, and the dust-proof feature ensures cleanliness and safety in your workplace.

The Rotary Screen also supports the more efficient operation of subsequent machines, optimizing the recycling process. Precisely separating valuable materials contributes to sustainable recycling. Therefore, at GMS Machine, we take pride in offering this crucial equipment to promote sustainable recycling across the industry. Emphasizing recycling and our commitment to preserving natural resources form the core of our business.

Rotary Screen

Rotary screens play a critical role in material conveying processes and are utilized in various industries.

Screws are generally produced in various standards, including pipe type, U type, and vertical type. The Rotary Screen produced by GMS Machine is a fundamental component in recycling processes, specifically designed as a durable and high-capacity equipment to clean and separate your materials. This equipment helps isolate valuable materials in a pure form by separating unwanted small particles and dust. As a result, your recycling processes become more effective and efficient, and the dust-proof feature ensures cleanliness and safety in your workplace.

The Rotary Screen also supports the more efficient operation of subsequent machines, optimizing the recycling process. Precisely separating valuable materials contributes to sustainable recycling. Therefore, at GMS Machine, we take pride in offering this crucial equipment to promote sustainable recycling across the industry. Emphasizing recycling and our commitment to preserving natural resources form the core of our business.

Vibration Conveyor

The Vibration Conveyor is an essential piece of equipment that ensures perfect material distribution and makes your business processes more efficient. This high-quality machine, produced by GMS Machine, conveys the material to the next step by vibrating and spreading it uniformly. This enhances material flow, making your workplace processes more effective and rapid.

At GMS Machine, we take pride in offering this vibration conveyor to the industry. The core objective of our business is to provide the highest quality equipment to enhance the efficiency of your operations and promote sustainability. Our expertise in recycling and material management contributes to the preservation of natural resources. Offering the best service to our customers and working towards a cleaner environment in the future are at the center of our vision.

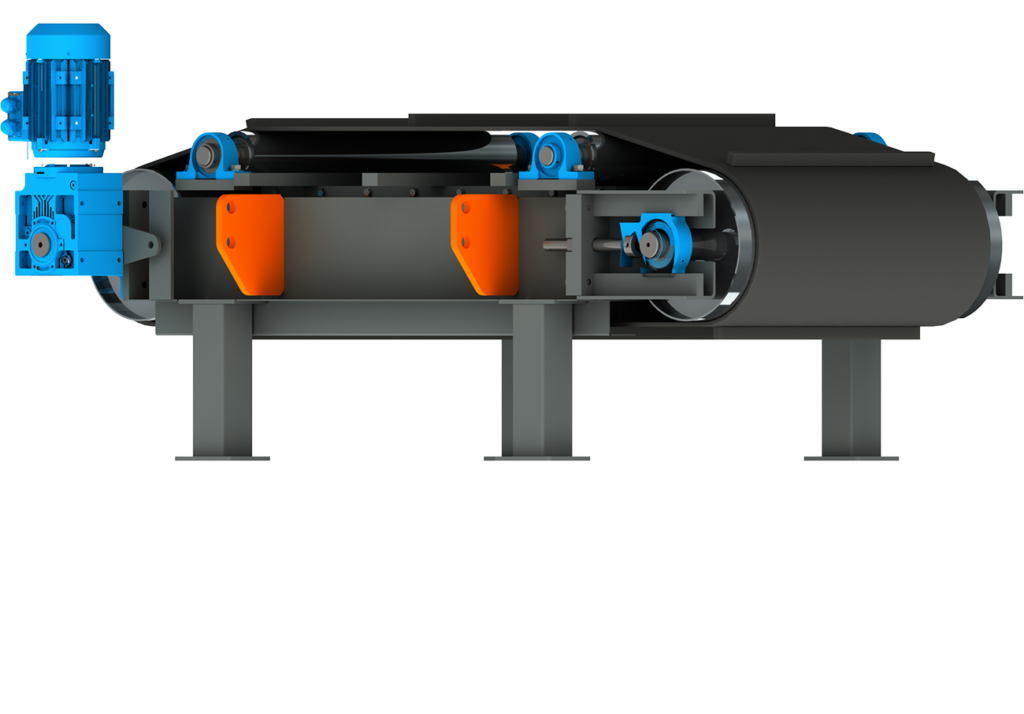

Eddy Current

EDDY Current non-ferrous metal separators are used in the separation of non-ferrous metals. Eddy current separators create an eddy current on a magnetic drum, which rotates on its own axis at a certain speed and is arranged in a specific fraction. This current attracts and accelerates non-ferrous materials coming at a certain speed, throwing them out of the current. Through this process, non-ferrous materials are effectively separated from other materials.

Eddy Current

EDDY Current non-ferrous metal separators are used in the separation of non-ferrous metals. Eddy current separators create an eddy current on a magnetic drum, which rotates on its own axis at a certain speed and is arranged in a specific fraction. This current attracts and accelerates non-ferrous materials coming at a certain speed, throwing them out of the current. Through this process, non-ferrous materials are effectively separated from other materials.

X-Ray

X-TRACT™ is a highly efficient sorting solution designed to detect and separate objects based on their atomic densities, harnessing the power of dual-energy X-ray transmission. The top-down design of the machine prevents dust and dirt from affecting the X-ray source, thus preventing costly maintenance. Additionally, it provides higher efficiency through more precise detection and optimal source-sensor positioning.

X-TRACT™ offers the capability of high-speed processing in various applications and particle sizes, including thin aluminum and copper wires, using an X-ray power source of up to 1000 W.

Thanks to its Dual Processing Technology, X-TRACT™ allows operators to sort composite materials and overlapping objects effortlessly, providing the opportunity for high recovery or high purity efficiency. Through Multiple Density Channels, utilizing software-defined intervals, X-TRACT™ is an ideal solution for classifying objects at high production speeds, recovering high-value materials from complex material flows.

Alüminyum Geri Dönüşüm Sistemi:

Amaç:

- Alüminyum geri dönüşüm sistemi, alüminyum malzemelerin geri kazanılması ve yeniden kullanılması amacıyla tasarlanmıştır, bu da birincil alüminyum üretimine duyulan ihtiyacı azaltır.

Toplama:

- Alüminyum geri dönüşümü, içecek kutuları, folyo, ambalaj malzemeleri ve endüstriyel hurdalar gibi kullanılmış alüminyum ürünlerinin toplanması ile başlar.

Ayırma:

- Toplanan alüminyum, diğer malzemelerden ayrılarak daha verimli bir geri dönüşüm süreci sağlanır.

Temizleme ve Parçalama:

- Ayıklanan alüminyum, kirleticileri çıkarmak için temizlenir ve daha sonra işlenmesi için küçük parçalara parçalanır.

Eritme:

- Parçalanmış alüminyum, yüksek sıcaklıklarda fırınlarda eritilir. Eritme süreci metalin sıvı formuna indirgenmesini sağlar.

Arıtma:

- Sıvı alüminyum, kalitesiz geri dönüştürülmüş alüminyumu ortadan kaldırmak için arıtma süreçlerinden geçebilir.

Dökme:

- Arıtılmış sıvı alüminyum, kullanım amaçlarına bağlı olarak kütük veya blok gibi farklı şekillerde dökülür.

Yeniden İmalat:

- Geri dönüştürülmüş alüminyum, alüminyum kutular, otomotiv parçaları, inşaat malzemeleri ve daha fazlası gibi çeşitli endüstrilerde yeni ürünlerin üretiminde kullanılır.

Enerji Tasarrufu:

- Alüminyum geri dönüşümü, birincil alüminyum üretimine kıyasla önemli ölçüde daha az enerji tüketir. Enerji tasarrufu, çevresel sürdürülebilirliğe katkıda bulunur.

Çevresel Faydalar:

- Alüminyum geri dönüşümü, boksit madeninin (alüminyumun başlıca kaynağı) madenciliği ve alüminyumun boksit madeninden çıkarılması sürecindeki enerji yoğunluğu ile ilişkili çevresel etkiyi azaltmaya yardımcı olur.

Ekonomik Etki:

- Alüminyum geri dönüşüm endüstrisi, iş yaratma, atık azaltma ve doğal kaynakların korunması konusunda önemli bir rol oynar.

Küresel Geri Dönüşüm Çabaları:

- Birçok ülke, döngüsel ekonomiyi teşvik etmek ve karbon ayak izini azaltmak amacıyla alüminyum geri dönüşümünü teşvik eden geri dönüşüm programları, girişimler ve düzenlemelerle destekler.

Alüminyum geri dönüşümü, sürdürülebilir atık yönetimi ve kaynak koruma açısından önemli bir konudur. Sadece enerji ve hammadde tasarrufu sağlamakla kalmaz, aynı zamanda alüminyum üretiminin çevresel etkisini azaltmaya yardımcı olur.