Spare parts

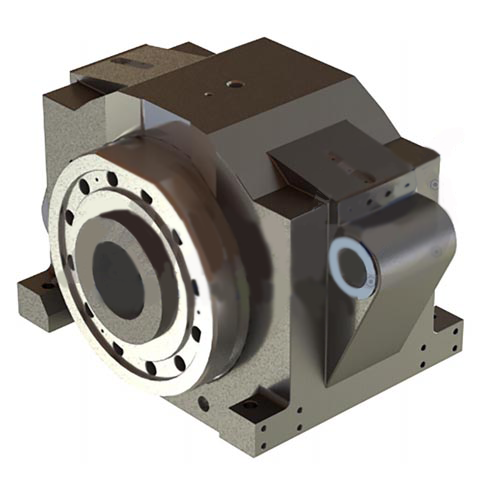

Extrusion Konteyner (kovan)

Tutucu(kalıp taşıyıcı)

Dummy Blocks

Konteyner taşıyıcısı

-Temizleme diski

-Kısa kesme bıçağı

-Bağlantı milleri

Sütunlar ve pres somunları

Destek ve halkalar

Zimba

Parlatma Makaraları

Hassas Makaralar

Rafine Makaraları

Isı Transferi ve Soğutma Makaraları

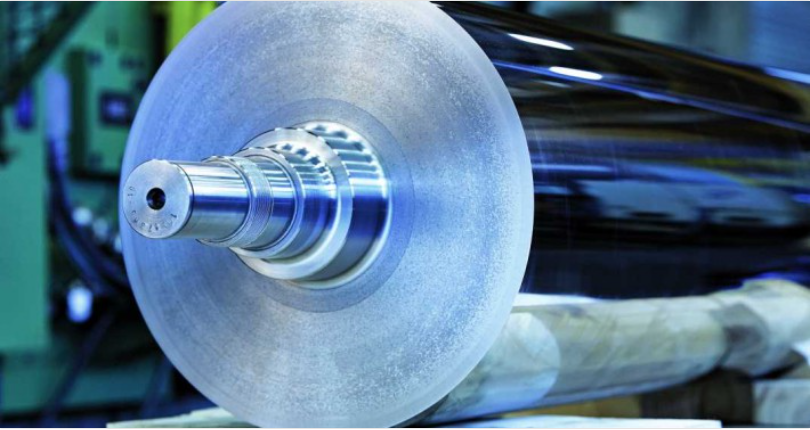

Graphic roll

Our precision-engineered cylinders are meticulously crafted and ready for deployment. We specialize in the production of cylinders tailored for gravure, screen, lacquer, color, impression, pressure, air, and offset printing.

Our versatile cylinders find application in various printing mediums, including:

- Paper

- Foil

- Laminates

- Embossing

- Metal

Coating and doctor rolls

Application Versatility: Coating and Doctor Rolls for Precision

Our coating and doctor rolls serve a diverse range of purposes, including coating, dyeing, and impregnating various materials such as plastic film, paper, textiles, fleece materials, and metal. The precision of the rollers is a critical factor in accurately dosing the quantity of material applied. At our facility, we take pride in the meticulous grinding of our finishing rolls, ensuring not only high precision but also exceptional corrosion resistance.

By investing in our high-precision finishing rolls, you gain the advantage of optimal dosing accuracy for your specific application, leading to superior results across a variety of materials. Explore the precision and durability of our rolls for your coating and doctoring needs.

Refiner Rolls

In the intricate world of chocolate production, refining rollers play a pivotal role in shaping the quality and smoothness of the final product. The precision of these refining rollers is paramount, as it directly influences the texture and overall quality of the chocolate. A key factor in achieving excellence lies in the wear resistance and cooling capacity of the rollers.

The wear-resistant nature of the refining rollers ensures prolonged durability, contributing to the economic value of chocolate production. Additionally, efficient cooling capabilities further enhance the consistency and quality of the chocolate product. By investing in high-quality refining rollers, you not only elevate the manufacturing process but also guarantee a superior end product. Choose precision, choose durability—choose refining rollers for a delectable journey in chocolate craftsmanship.

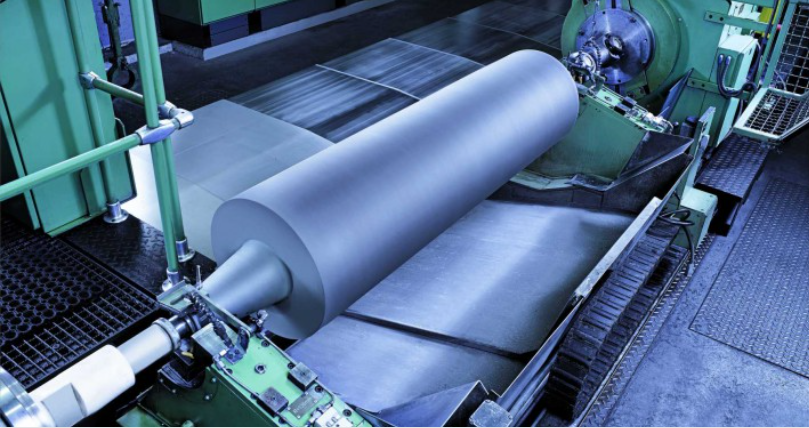

Calender Rolls

Calendering, a sophisticated industrial technique, involves the transformation of a thermoplastic mass into a foil by passing it through two or more rollers. This process begins with heating and kneading the plastic thermoplastic mass into a viscous state, followed by shaping it between rollers into a cooled foil or strip of specific thickness. The resulting strip or foil can serve as the final product or act as a semi-finished material.

Calender rolls play a critical role in producing plastic foil and rubber products. The quality of the calender rollers is paramount, necessitating the exclusion of even the minutest defects such as pores or cracks on the roll surface. The precision of the calender rolls’ grinding process directly influences product tolerance values, emphasizing the importance of meticulous craftsmanship for achieving the highest possible product quality. Elevate your foil production with our precisely crafted calender rolls for superior results.

Flaking Rolls

Smooth rolls play a vital role in the squeezing process within roller mills. The effectiveness of the squeezing behavior directly influences the production reliability of the entire system. As the smooth roll excels in its squeezing performance, it contributes significantly to the seamless operation and enhanced efficiency of the roller mill.